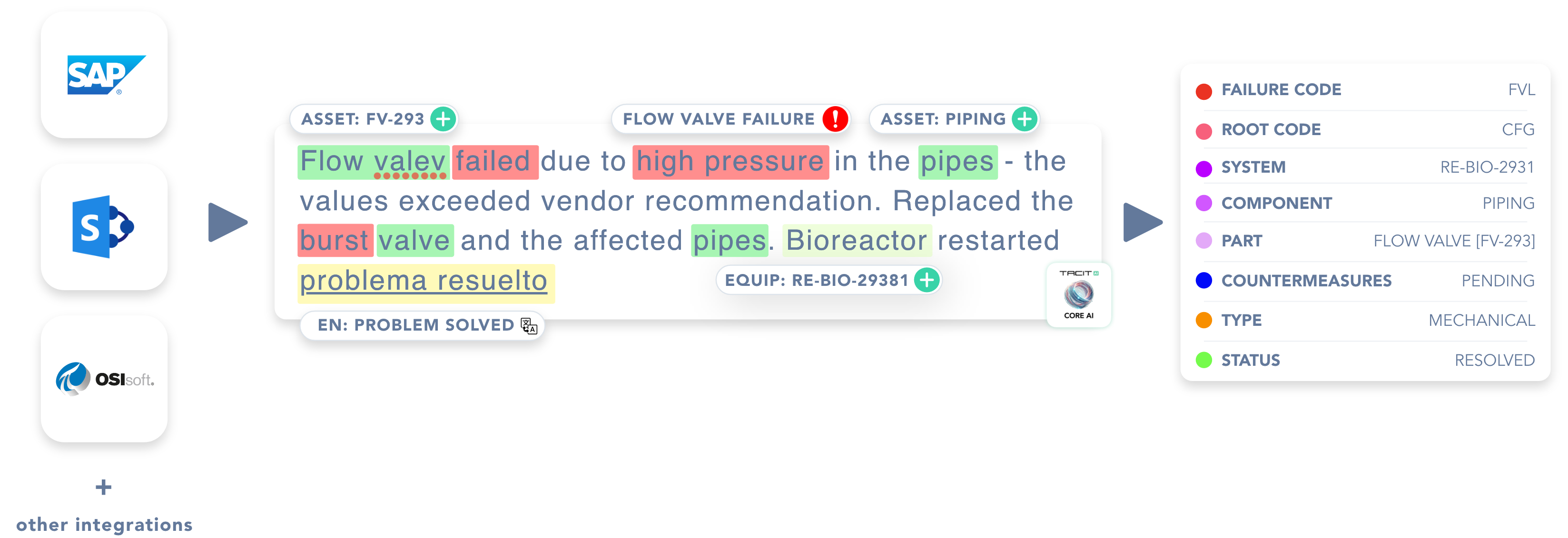

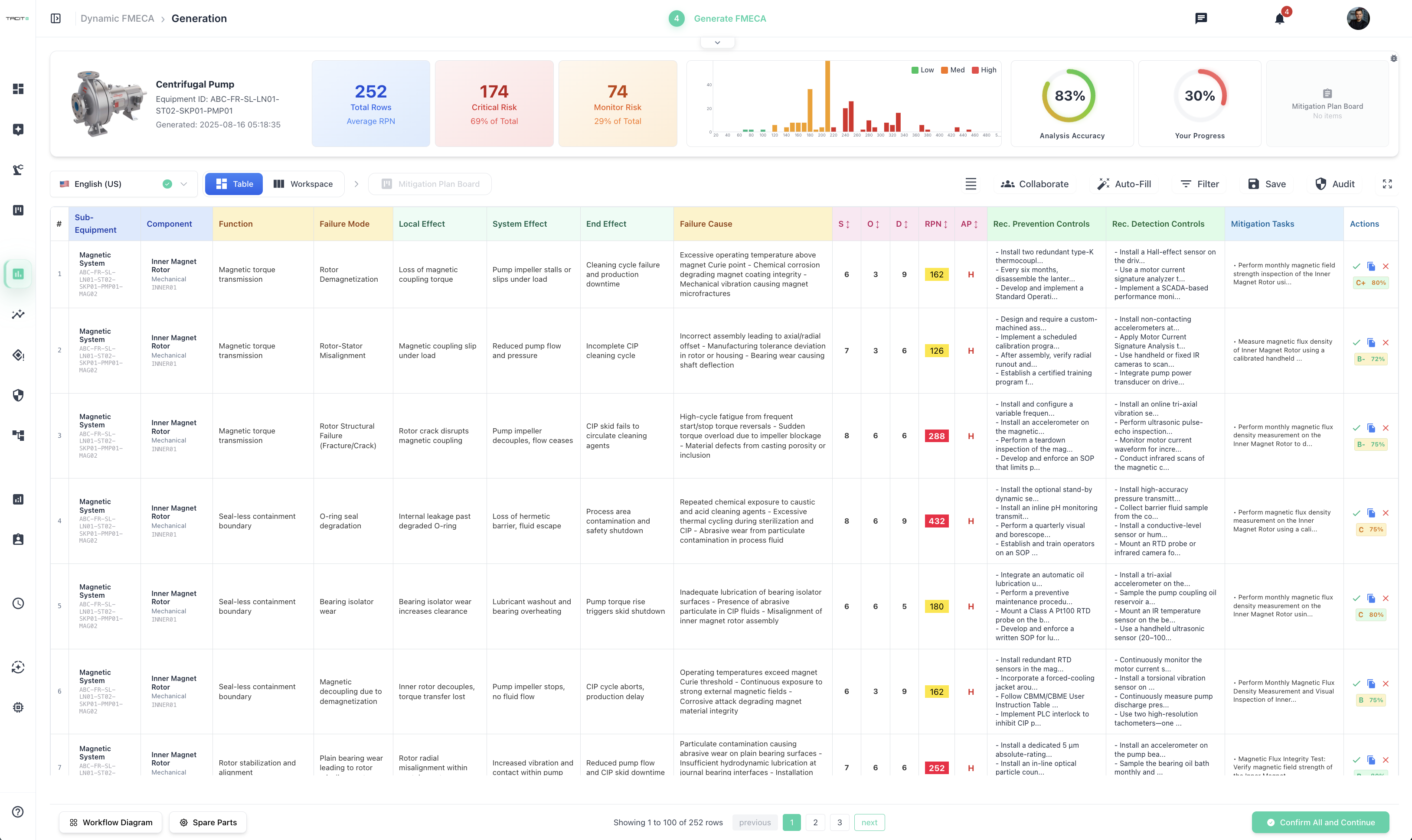

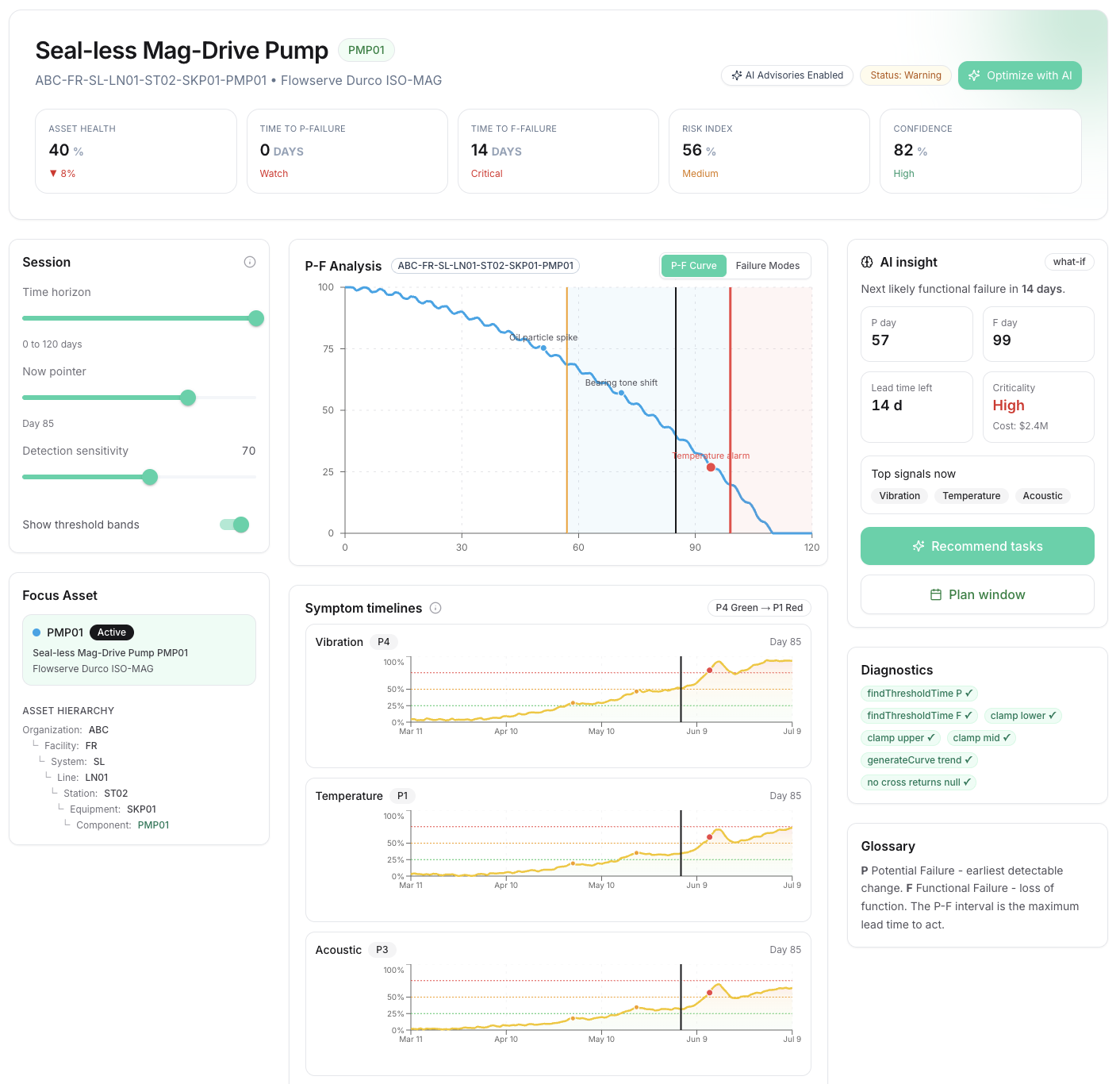

Tacit AI reads years of work orders, alarms, and maintenance notes and turns them into a ranked list of bad actors, root causes, and recommended tasks. Within a week, your team knows exactly which assets and failure modes to attack first. Behind the scenes, Tacit keeps your DFMEAs, PFMEAs, and FMECAs in sync with what’s actually happening – without anyone living in spreadsheets.

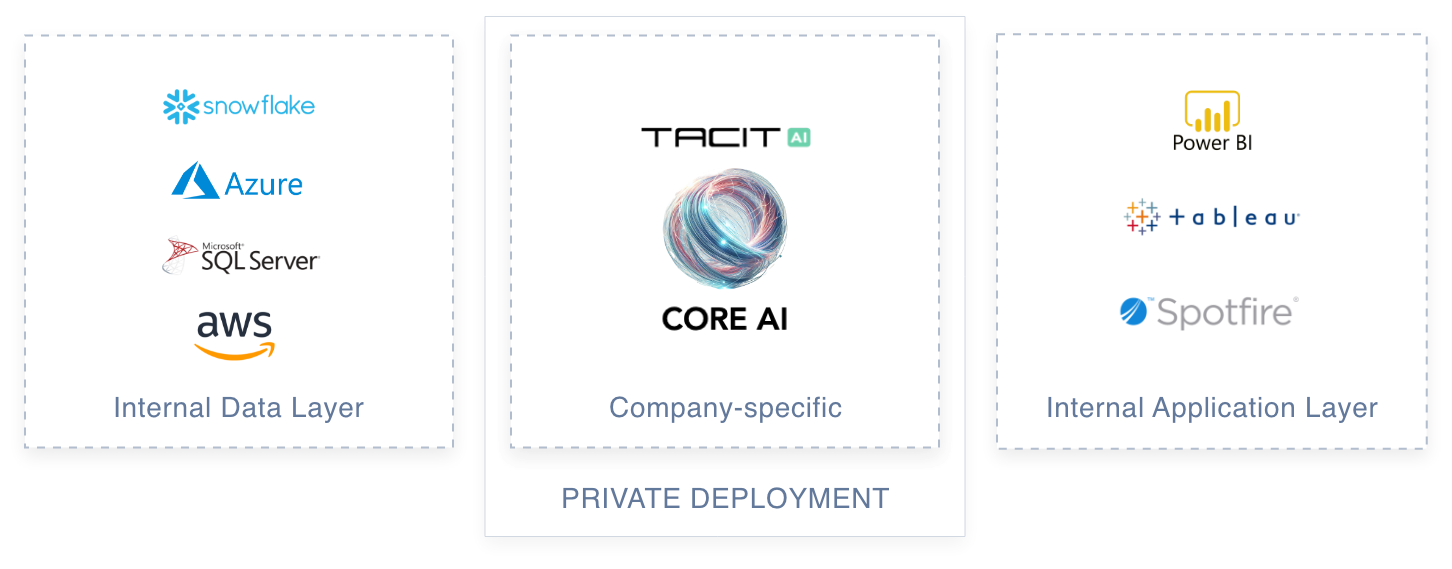

No IT project required. Start with existing data, definitions and templates.

Introducing

Powered by

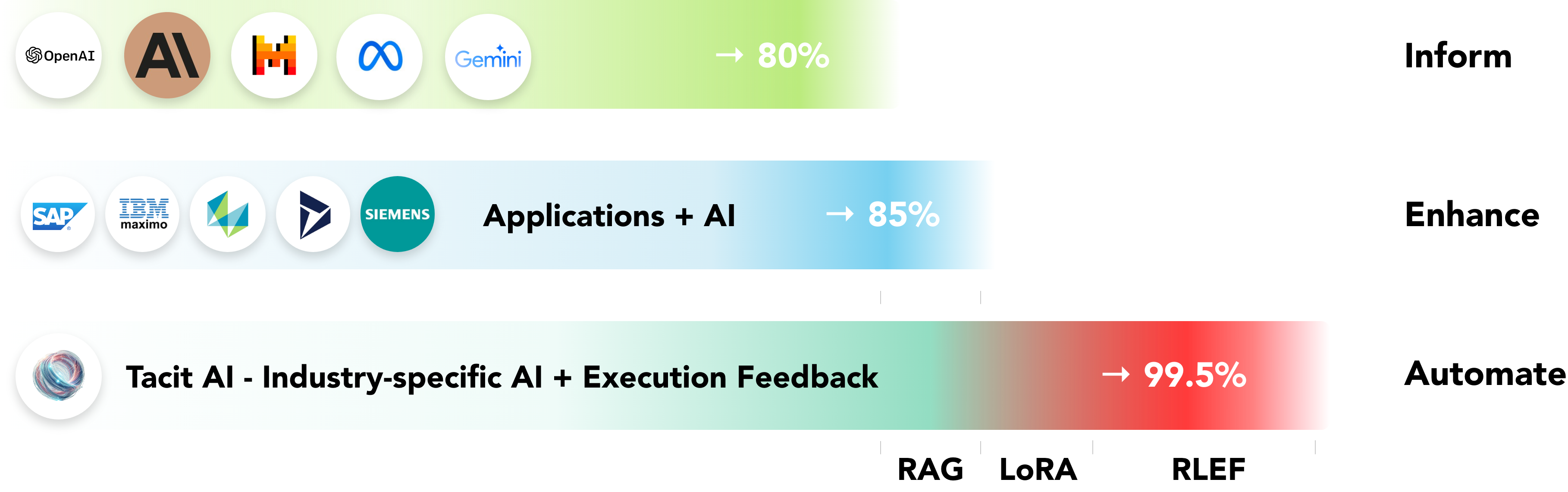

Continuous learning from vast amounts of technical knowledge

Real-time interactions with the user to for 2-3x faster decisions

Empowered contextual understanding and recommendations

Contextual understanding and classification of unstructured data

Preventative maintenance optimization and data quality analysis

Frontline skills and optimal work allocation and scheduling

Figures aggregated from case studies. Get in touch to discover customized strategies to reduce downtime, optimize preventative maintenance, automate reporting and transform data quality, while retaining technical expertise forever.

Tacit AI accelerates engineering performance by closing data & knowledge gaps in real time and continuously optimizing equipment, process and design strategies in high criticality and complexity industries.

Run a 3‑week pilot on 1 system. Expand site‑wide.

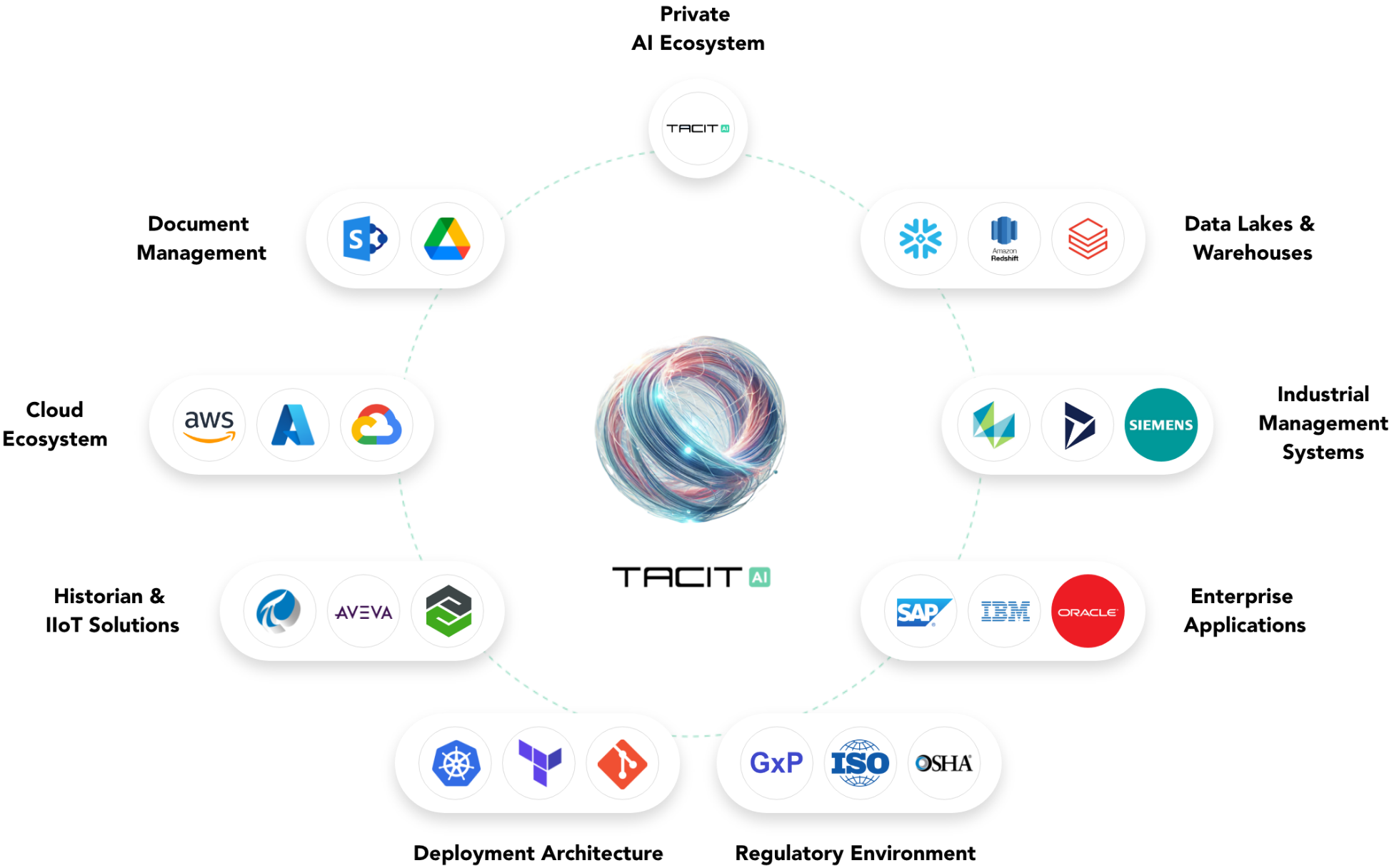

Tacit AI makes it easier, safer and faster for your team to achieve world-class results. You won’t have to deal with difficult infrastructure challenges, finding and hiring talent, trial and error, and ever-increasing timelines. Our rare team of engineers has both the technical, manufacturing and business expertise to build, integrate, maintain and continuously improve the human-centric AI layer fine-tuned to augment your manufacturing ecosystem

Join an exclusive community of manufacturing innovators. Stay up to date with Tacit AI events, new releases and actively contribute to the future of manufacturing

Tacit AI is a technology company with offices in the United States and the United Kingdom

© 2025 Tacit AI, Inc.

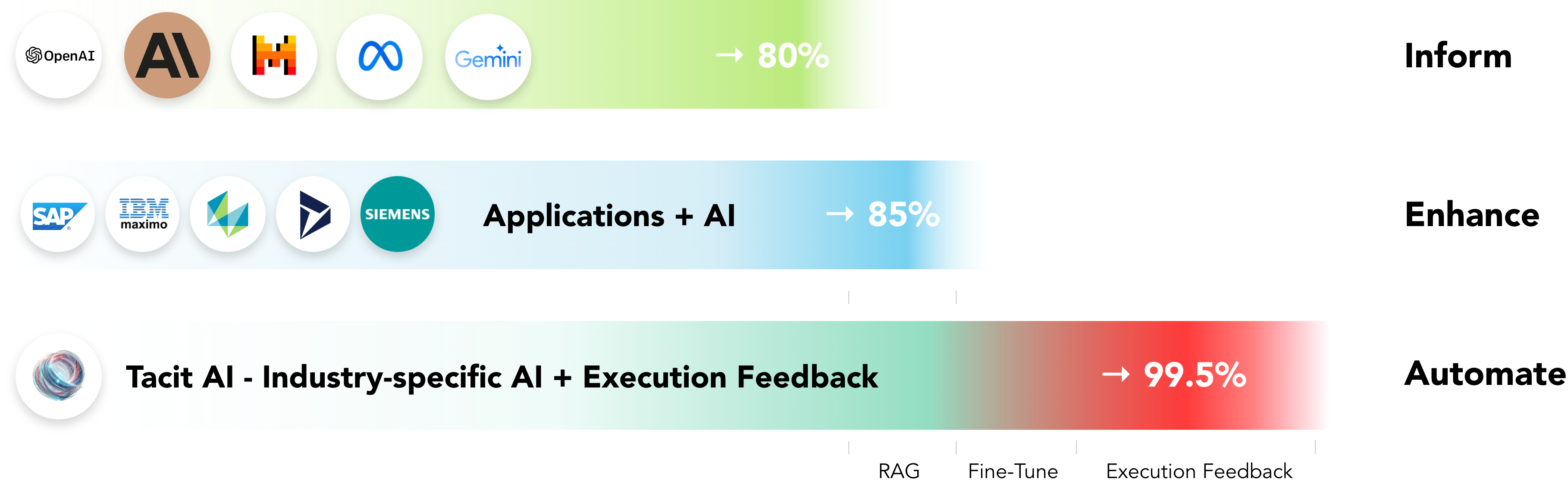

Platform

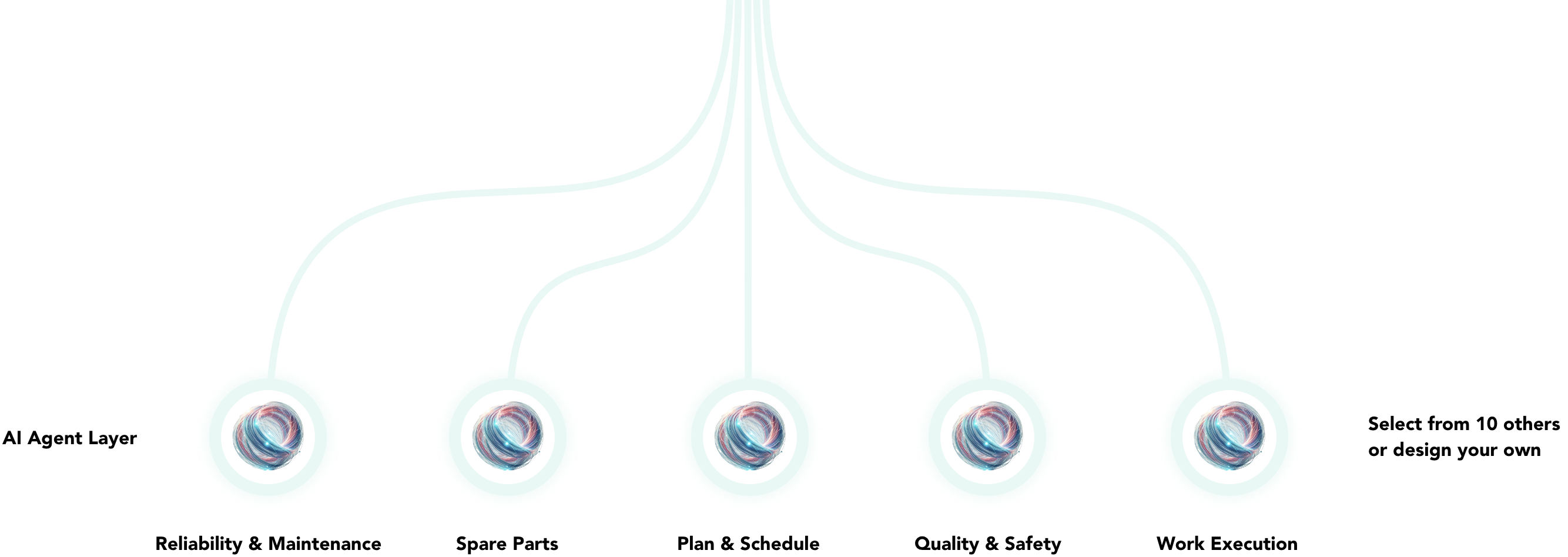

Applications

Others