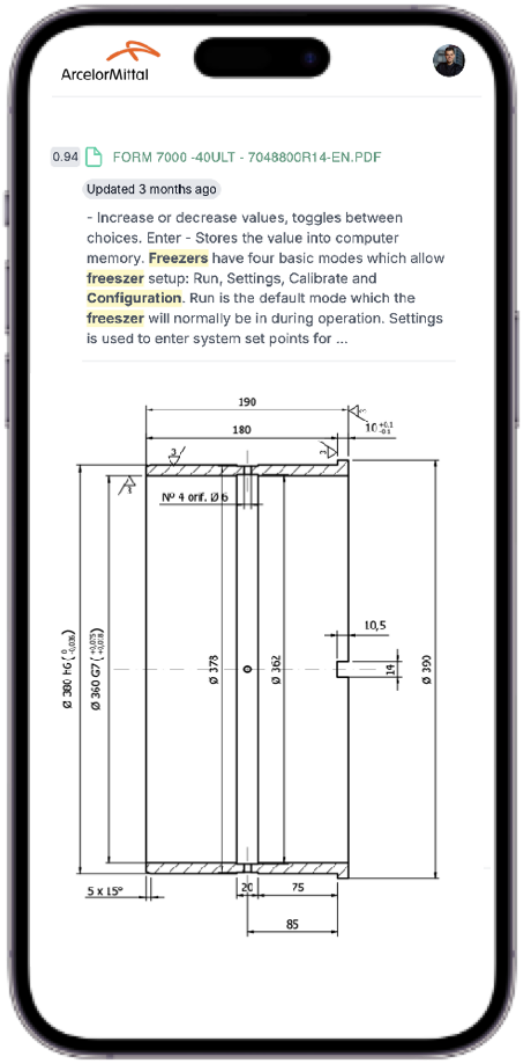

Tacit AI helped us access manuals, drawings, and procedures instantly, reducing desk trips. Field teams spend more time on assets, improving work cycle and wrench times. The rolling mill pilot is just the beginning in our digital transformation journey.

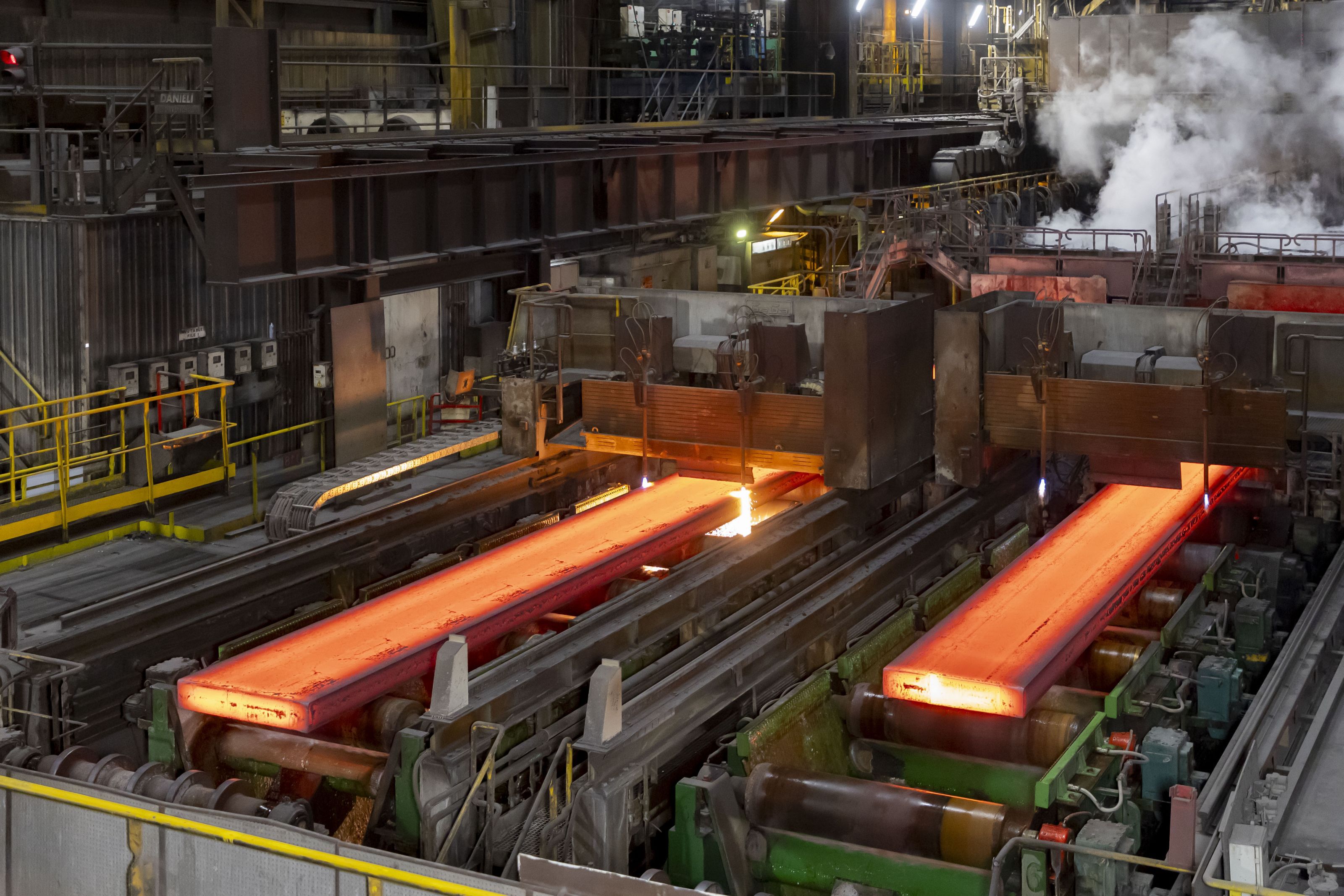

ArcelorMittal Hunedoara faced inefficiencies in its rolling mill lines due to fragmented technical documentation access. Workers frequently left the production floor to locate, translate, and print manuals, procedures, and work orders, taking 43 minutes to find technical documents through a cumbersome process that reduced first-time fix rates and extended repair cycles.

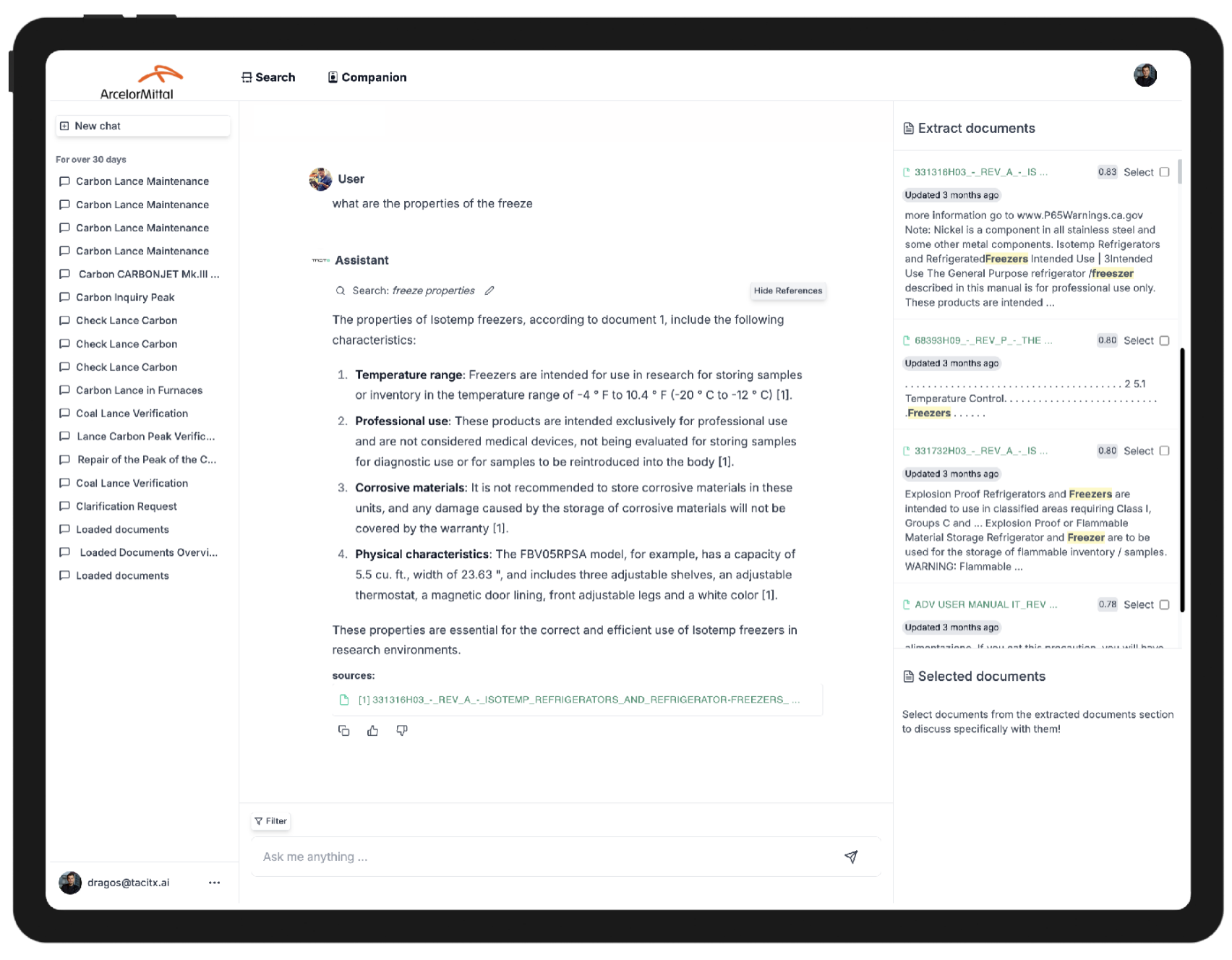

Workers can search, view, and translate manuals in real time, reducing repair times and improving first-time fix rates

AI consolidated manuals, procedures, and work orders into a searchable knowledge graph, enabling fast, accurate access to critical information

The pilot deployment on our rolling mill demonstrates the transformative potential of AI in our operations. Our engineers now have instant access to critical information, allowing them to focus on what matters most – keeping our assets running efficiently and safely.